Okay, I apologize... but this is going to be a pic heavy disassembly and I'm stuck at the end, so I could use a lil help...

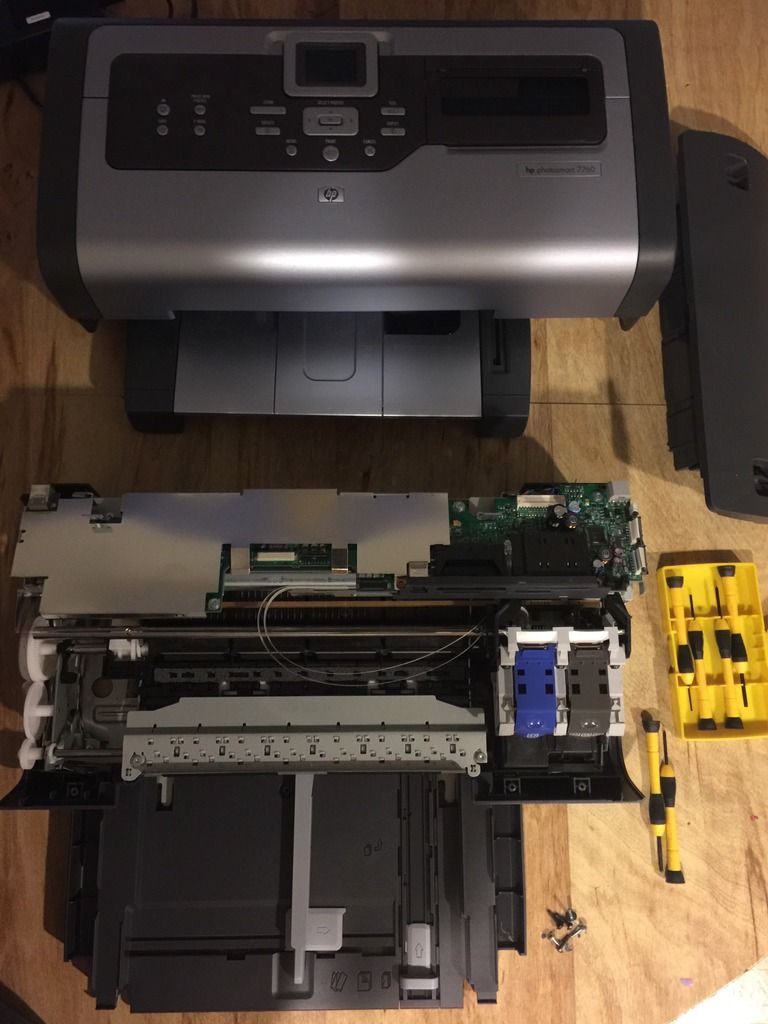

Went to local thrift store and got this for $8, brand new not in box but still had the tape and plastic screen guards on the easy scratch plastic parts and screen so good deal!!!

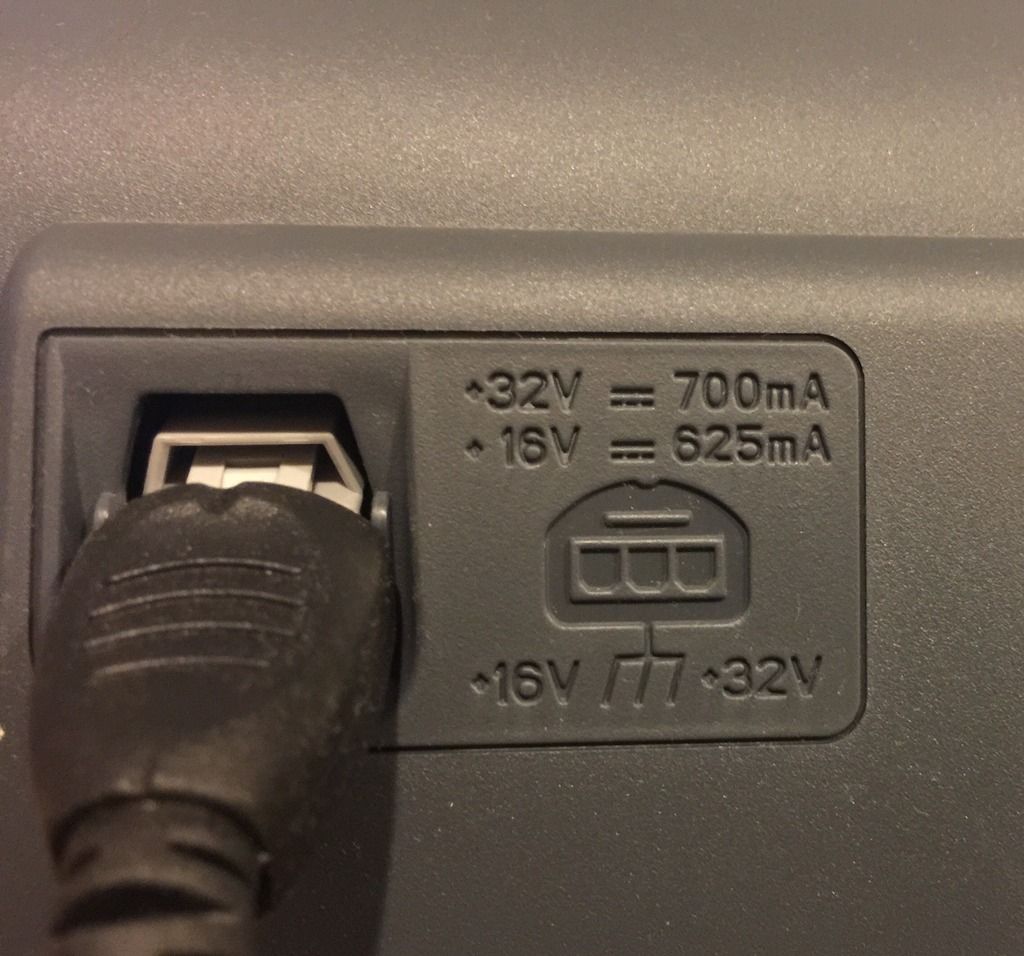

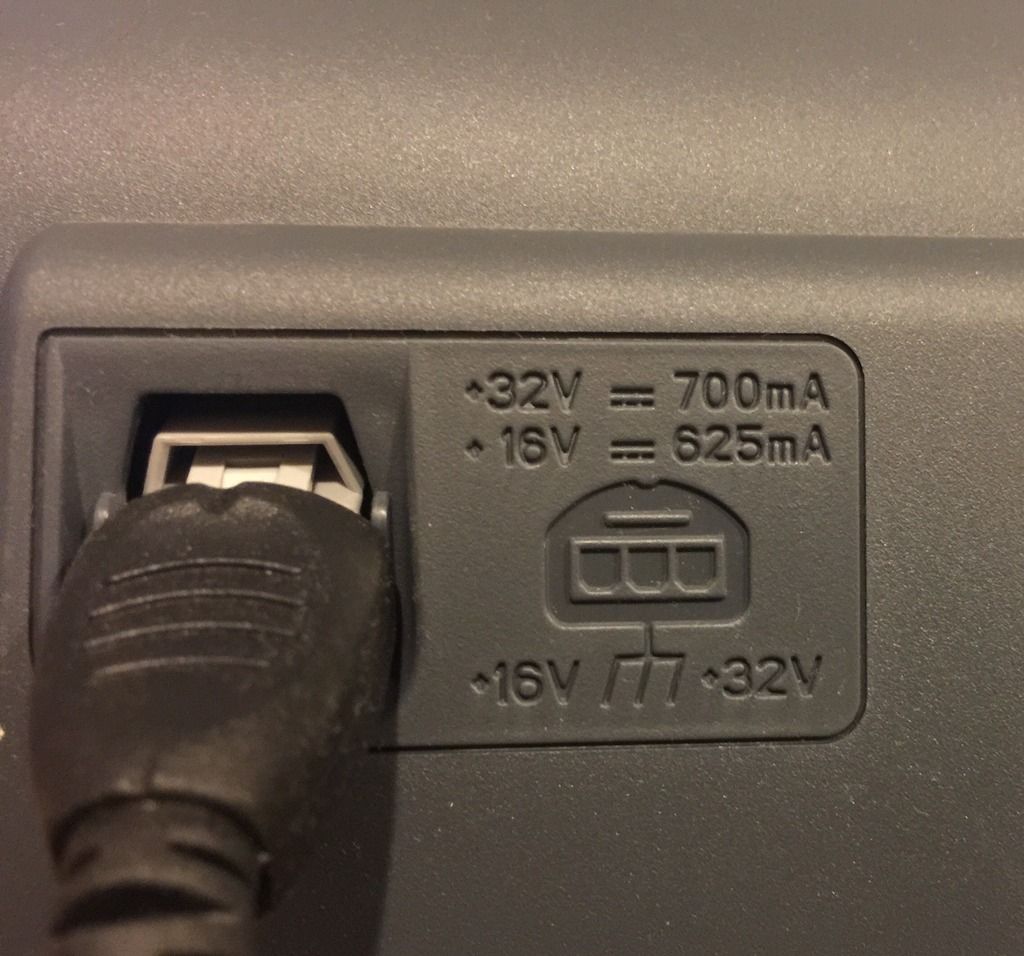

And I know what you were talking about with the 32v and 16 volt, mine says the same but the plug has a built in converter that put out 32v and 16v respectively....

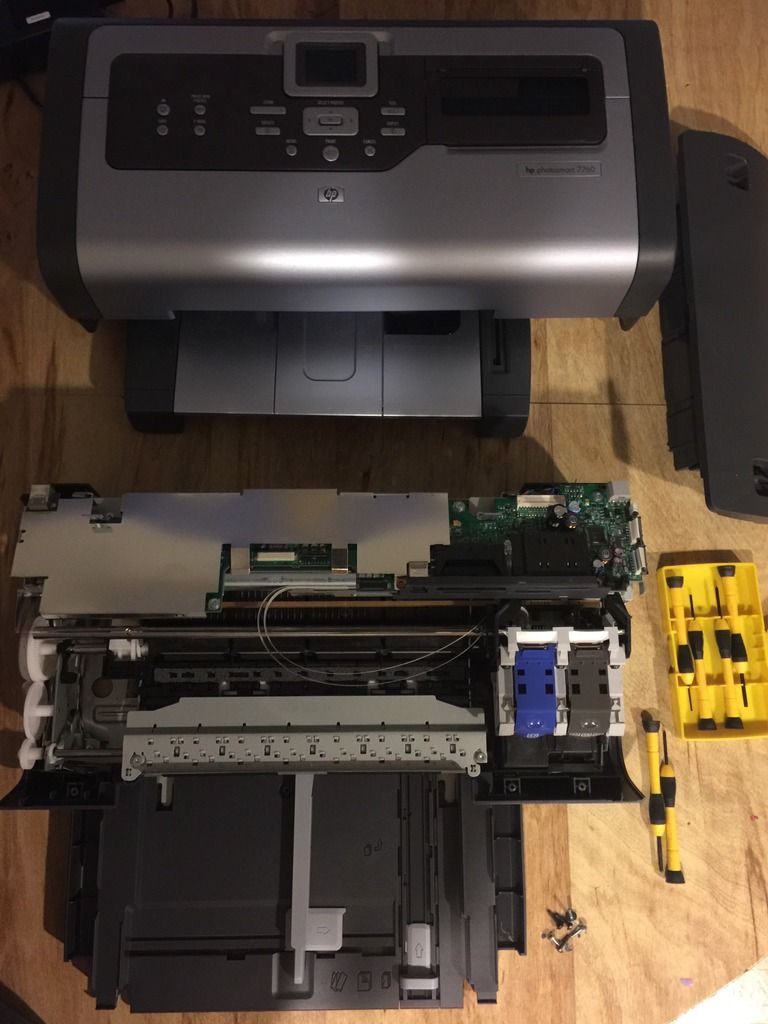

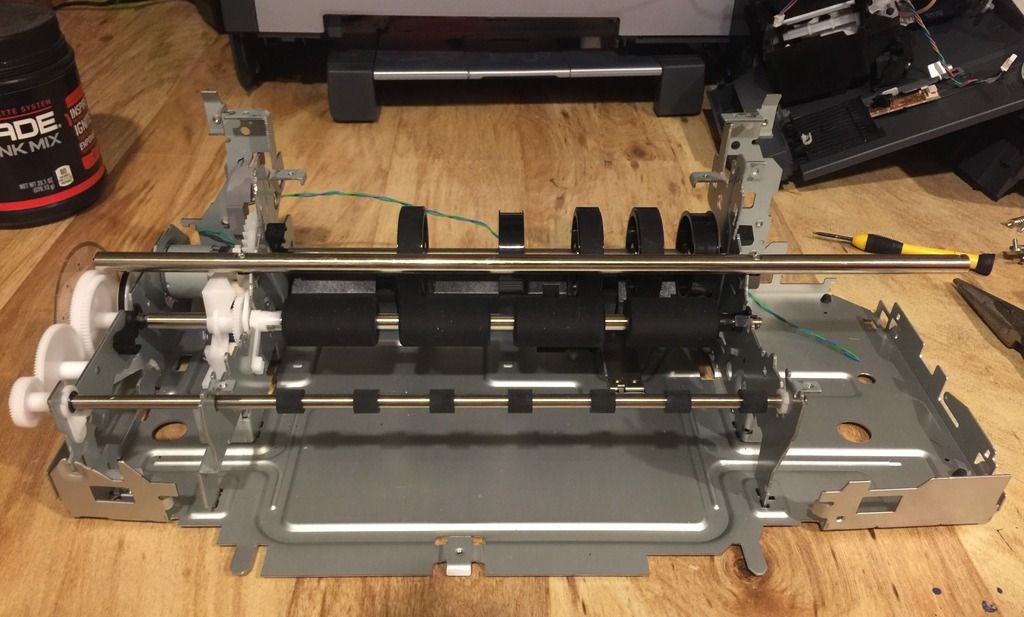

6 torx screws later and the top cover comes off with a few other pieces of the printer...

Few more screws as you can see in the pile, and we're about halfway there after 20 minutes with figuring where to unclip some plastic pieces from also...

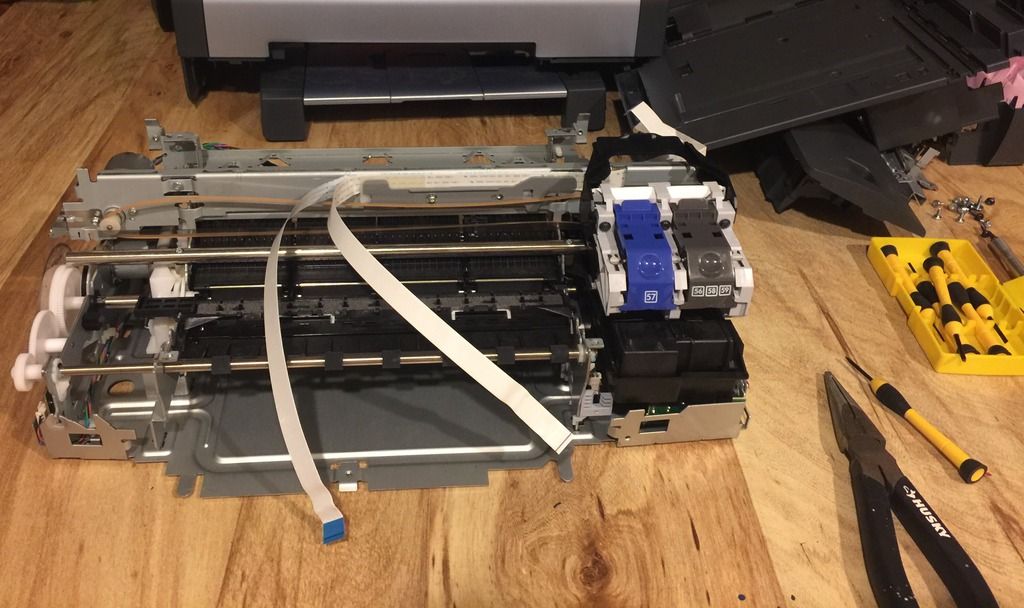

*Pro-tip* BE VERY CAREFUL: These electronics, like most, are make with sharp thin metal and will slice your fingers, arm and head off if you somehow manage to get it in there close enough!!!

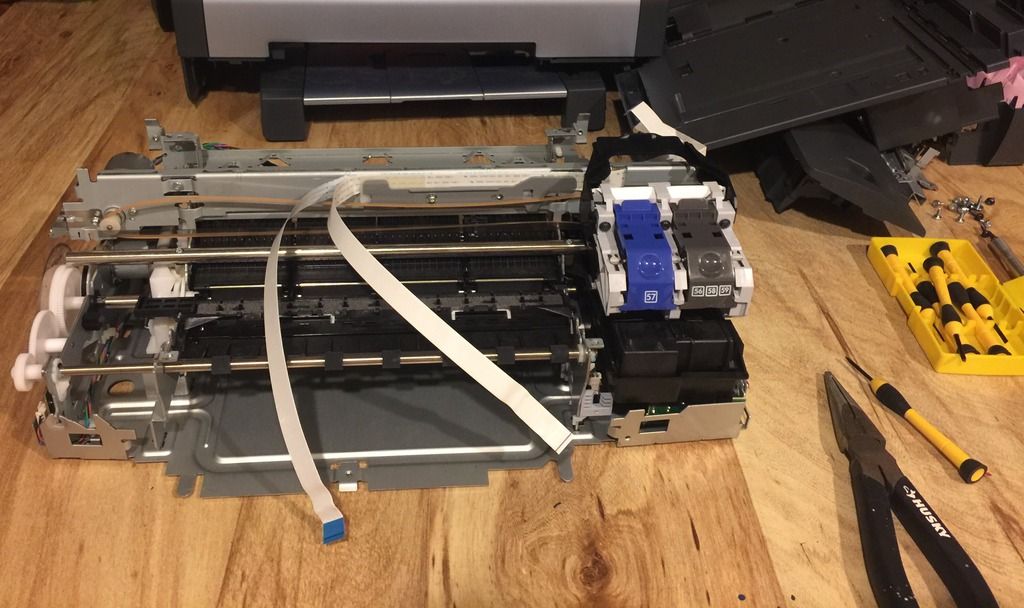

Ink cartridges out and no ink on the hands (bonus) because this was a new machine...

Now for the help I need....

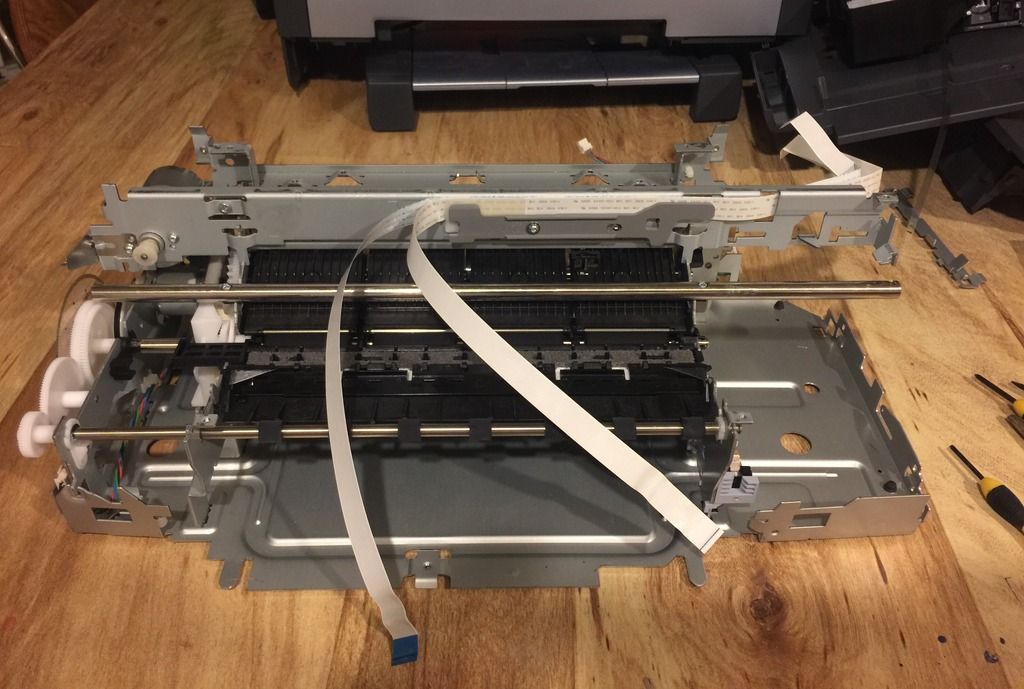

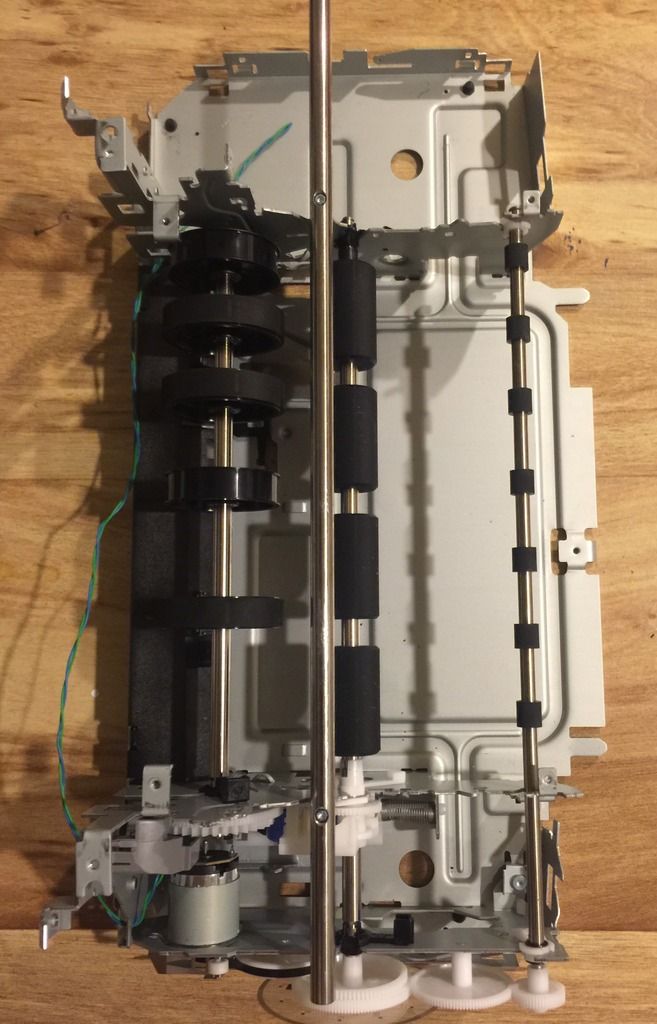

The sides holding the spindles look to be welded of sorts to the very bottom platform metal? I don't know what it's called but the best way I can think to describe it is like a rivet or button type weld or solder maybe? Take a look...

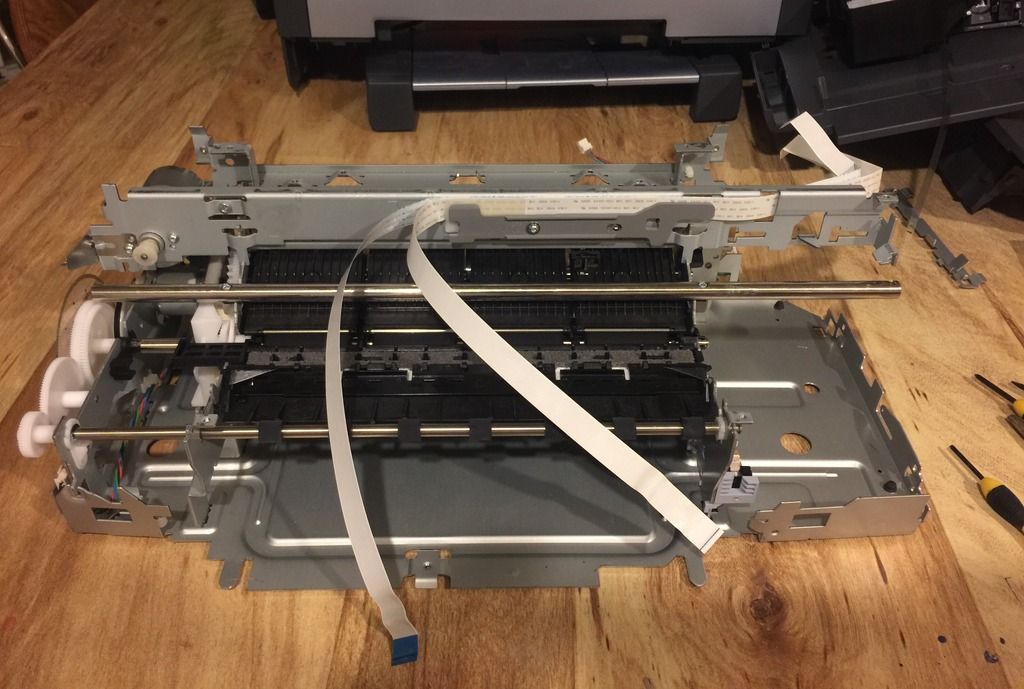

and the bottom side underneath...

I want to mount this on wood like the OP, so do these need to be drilled out with a small bit or does anyone know how to go about getting the sides undone from the base?

Or would it be better to just leave the sides attached to the base and run it like that? I was thinking if I could spread the rollers out a few inches, it might balance a tumbler jar better and less chance of it getting speed and flying off the rails.

Anyways, I hope this pictured disassembly helps someone and appreciate any advice you guys might have!!!