Dusty Eagle

Forum Supporter

I was thinking about making a tumbler, but trying to keep the project low budget, similar to the ones mentioned before in other message boards.

http://metaldetectingforum.com/showthread.php?t=14194&highlight=tumbler

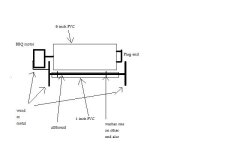

I say low budget but my wife sometimes compares me to Tim Allen/Tim Taylor on Tool Time. , but for my tumbler, I already have several components. I have 4" Sch40 PVC pipe, and had a 4" threaded plug left over from other plumping projects. I figured I could use a toilet tank bolt with rubber washer if needed, for the cap and have an assortment of other bolts, bushings and hardware in my shop. I've been looking for some type of motor though, even from the local hardware stores, until I came across one that I had found in my shop today. It's from a 50 year old garage door opener. I check for continuity and it seemed to be ok so I plugged it in. Dang if it didn't work!

, but for my tumbler, I already have several components. I have 4" Sch40 PVC pipe, and had a 4" threaded plug left over from other plumping projects. I figured I could use a toilet tank bolt with rubber washer if needed, for the cap and have an assortment of other bolts, bushings and hardware in my shop. I've been looking for some type of motor though, even from the local hardware stores, until I came across one that I had found in my shop today. It's from a 50 year old garage door opener. I check for continuity and it seemed to be ok so I plugged it in. Dang if it didn't work!

My question is this. What is the speed, RPM that coin/rock tumblers need to run at to be effective for coin polishing?

The motor runs at 1800 rpm with a 1/2" shaft. it currently has 1" V-belt pulley on it. I have some other pulleys recovered from the garage door opening as well. I need to try and find the speed required, so I can see if I can step down the motor, or if possible, run it through a potentiometer switch to make it variable speed. Any suggestions?

Dusty Eagle

http://metaldetectingforum.com/showthread.php?t=14194&highlight=tumbler

I say low budget but my wife sometimes compares me to Tim Allen/Tim Taylor on Tool Time.

, but for my tumbler, I already have several components. I have 4" Sch40 PVC pipe, and had a 4" threaded plug left over from other plumping projects. I figured I could use a toilet tank bolt with rubber washer if needed, for the cap and have an assortment of other bolts, bushings and hardware in my shop. I've been looking for some type of motor though, even from the local hardware stores, until I came across one that I had found in my shop today. It's from a 50 year old garage door opener. I check for continuity and it seemed to be ok so I plugged it in. Dang if it didn't work!

, but for my tumbler, I already have several components. I have 4" Sch40 PVC pipe, and had a 4" threaded plug left over from other plumping projects. I figured I could use a toilet tank bolt with rubber washer if needed, for the cap and have an assortment of other bolts, bushings and hardware in my shop. I've been looking for some type of motor though, even from the local hardware stores, until I came across one that I had found in my shop today. It's from a 50 year old garage door opener. I check for continuity and it seemed to be ok so I plugged it in. Dang if it didn't work!

My question is this. What is the speed, RPM that coin/rock tumblers need to run at to be effective for coin polishing?

The motor runs at 1800 rpm with a 1/2" shaft. it currently has 1" V-belt pulley on it. I have some other pulleys recovered from the garage door opening as well. I need to try and find the speed required, so I can see if I can step down the motor, or if possible, run it through a potentiometer switch to make it variable speed. Any suggestions?

Dusty Eagle